FIBERGLASS, PLASTIC THERMOFORMING, COMPOSITES

Fiberglass Reinforced Plastic (FRP) Tanks have been used for many years as a containment solution for wide range of liquids that might corrode or interact with tanks made from non-resinous materials. Fiberglass and resin binds a strong matrix that is almost as durable as metal. Fiberglass can be underground or above surface.

MANUFACTURING METHODS:

- Filament winding process

- Contact moulding

- Chopped spray

TANK SPECIFICATION:

- Vertical or Horizontal

- Cylindrical or Rectangular

- Dome Top, Open Top, Custom Top

- Flat Bottom, Dished Bottom, Conical Bottom

- Capsule Type

WASTE WATER

Steintek's Engineered FRP Products offer long-lasting and extremely low maintenance advantages. It is lightweight, strong, corrosion resistant, and can be retrofitted to existing municipal and industrial pollution control systems. It can be used for septic tanks, greasetraps, scrubbers, storage chambers, FRP lining, FRP Filters, Manway covers, FRP pipes and Chemical ducting.

Baffle Walls

Garbage Chute

CONSTRUCTION

Engineers are looking for new materials that can be used to prolong and extend the services lives while maintaining durability and functionality. With this, Fiber reinforced polymers (FRPs), a relatively new class of non-corrosive, high strength to weight ratio has emerged as a practical alternative for several engineering applications.

ACCESSORIES

Fiberglass can be used to fabricate market standard parts that serves as an alternative to steel.

Pipe Flanges

OTHER FIBERGLASS APPLICATIONS

FRP Tanks for water, fuel oil, chemical and waste water

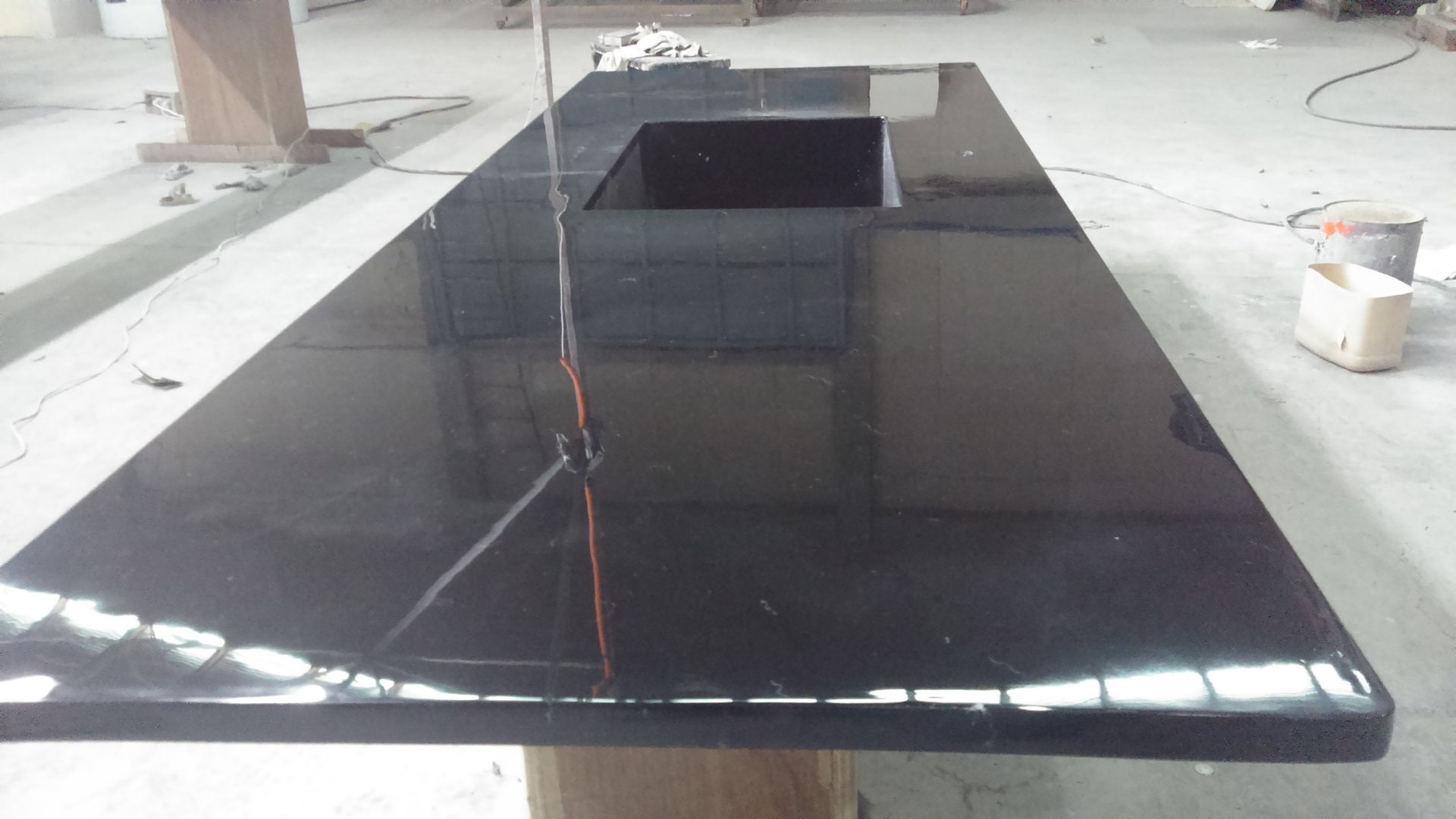

Chemical resistant fiberglass table and countertop

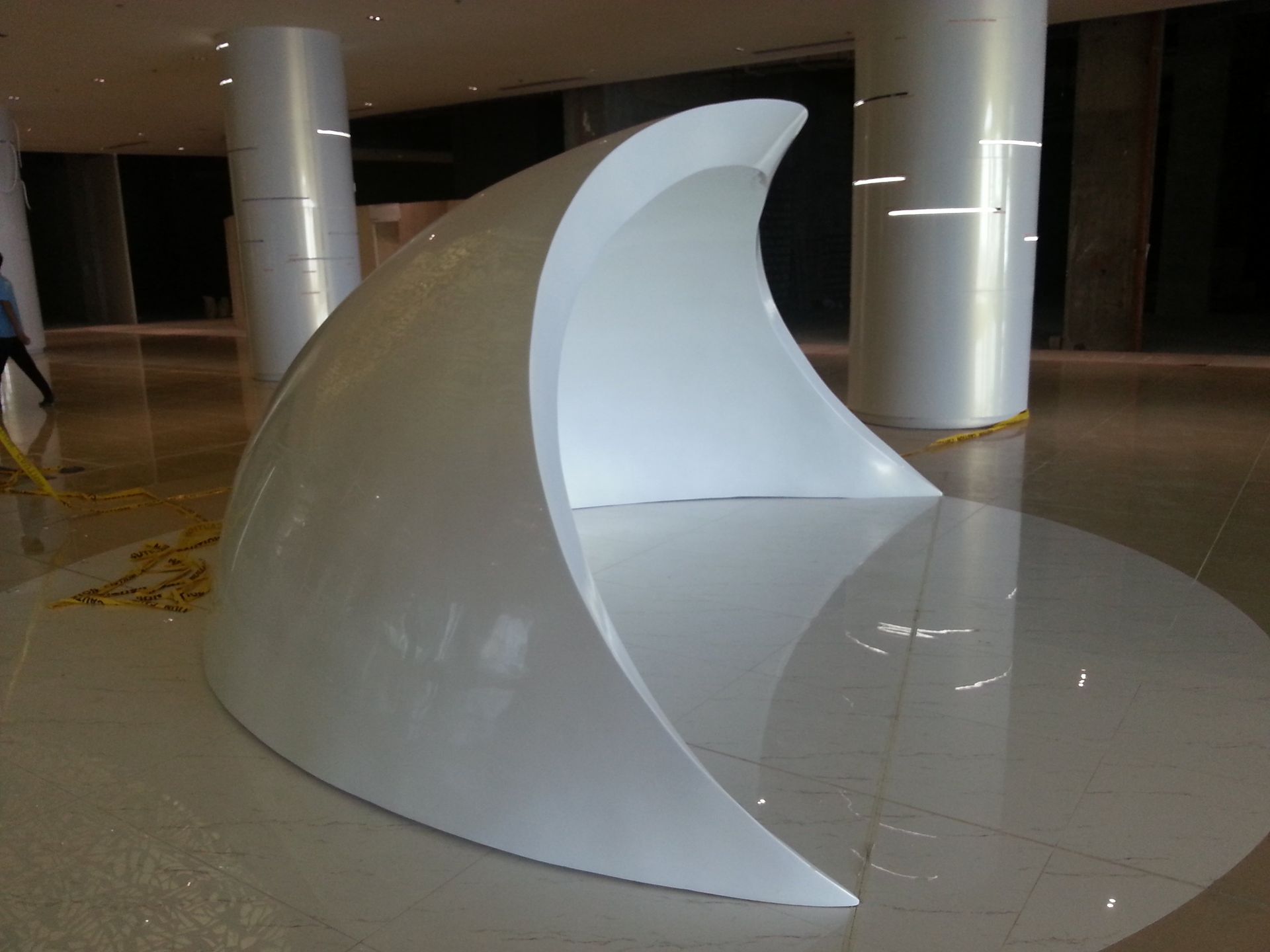

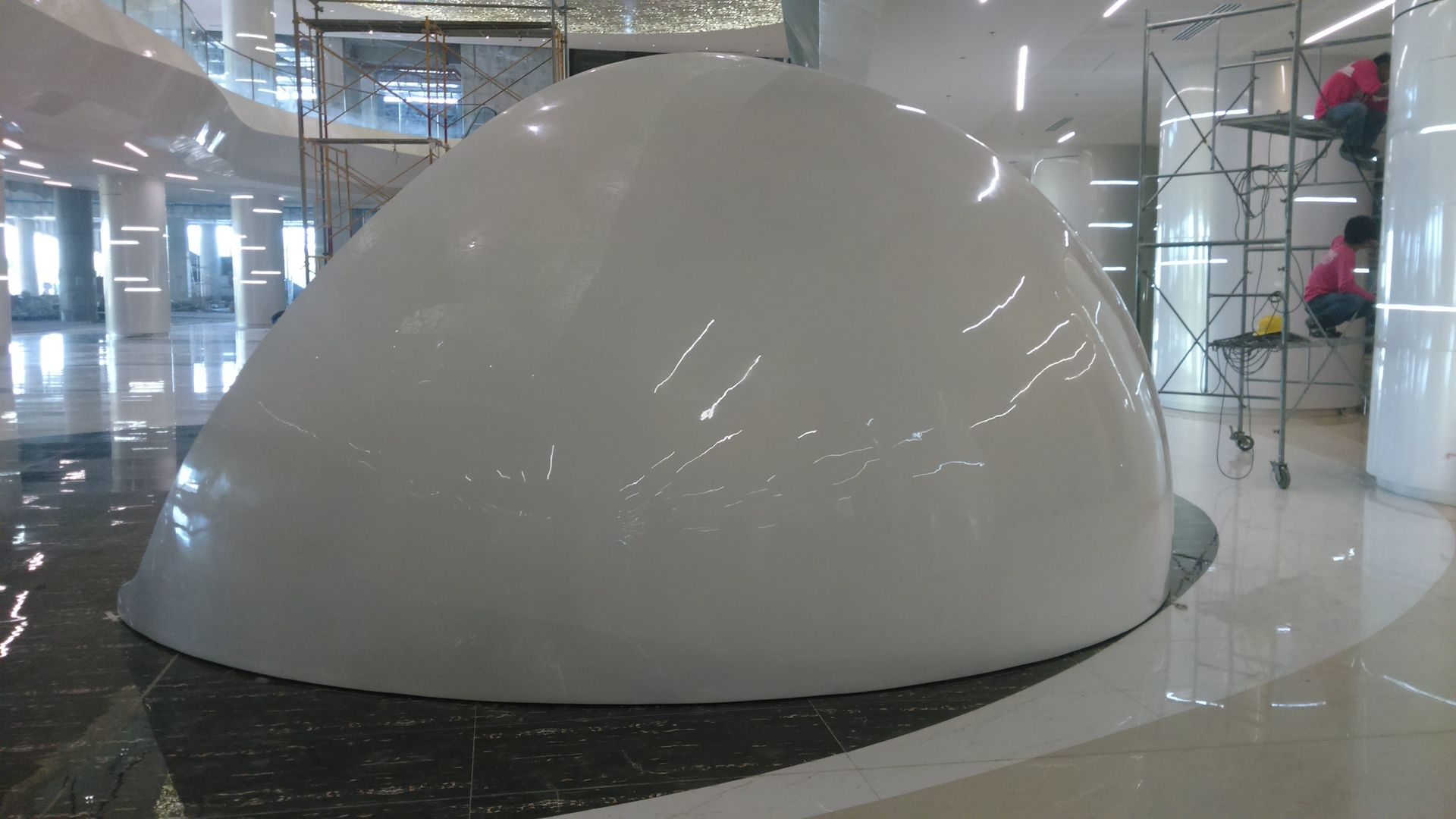

Architectural Pods

Garbage Chute for medium to high rise buildings

Fiberglass Windmills

Composite electric pole

OTHER THERMOFORMING APPLICATIONS

Taxi Cab Ads

Tricycles

Delivery Box